Consequences of Low Insulation on Humidity and Moisture

Low insulation in an attic can significantly impact both relative humidity and moisture levels. Here's how:

🌡️ Consequences of Low Insulation on Humidity and Moisture

1. Increased Condensation Risk

- Warm air from inside the home rises and enters the poorly insulated attic.

- When this warm, moist air meets the colder roof surface (especially in winter), it condenses.

- This leads to moisture accumulation on wooden structures, which can cause mold and rot.

2. Humidity Imbalance

- Without insulation acting as a barrier, indoor air (with higher relative humidity) escapes into the attic.

- This raises the attic's relative humidity, creating a moist microclimate that can damage insulation, wood, and stored items.

3. Mold and Mildew Growth

- Persistently high humidity from poor insulation creates an ideal environment for mold spores to thrive.

- Mold growth affects indoor air quality and can lead to structural degradation.

4. Ice Dams (in cold climates)

- Warm air from the living space melts snow on the roof, which refreezes at the eaves.

- This leads to water backing up under shingles and leaking into the attic, increasing moisture issues.

5. Decreased Energy Efficiency

- Moisture-laden air affects the performance of HVAC systems.

- High attic humidity can cause HVAC units in the attic to work harder, raising energy bills.

🛠️ Preventive Tips

- Improve insulation (e.g., fiberglass batts, blown-in cellulose).

- Seal attic air leaks (around pipes, lights, attic hatches).

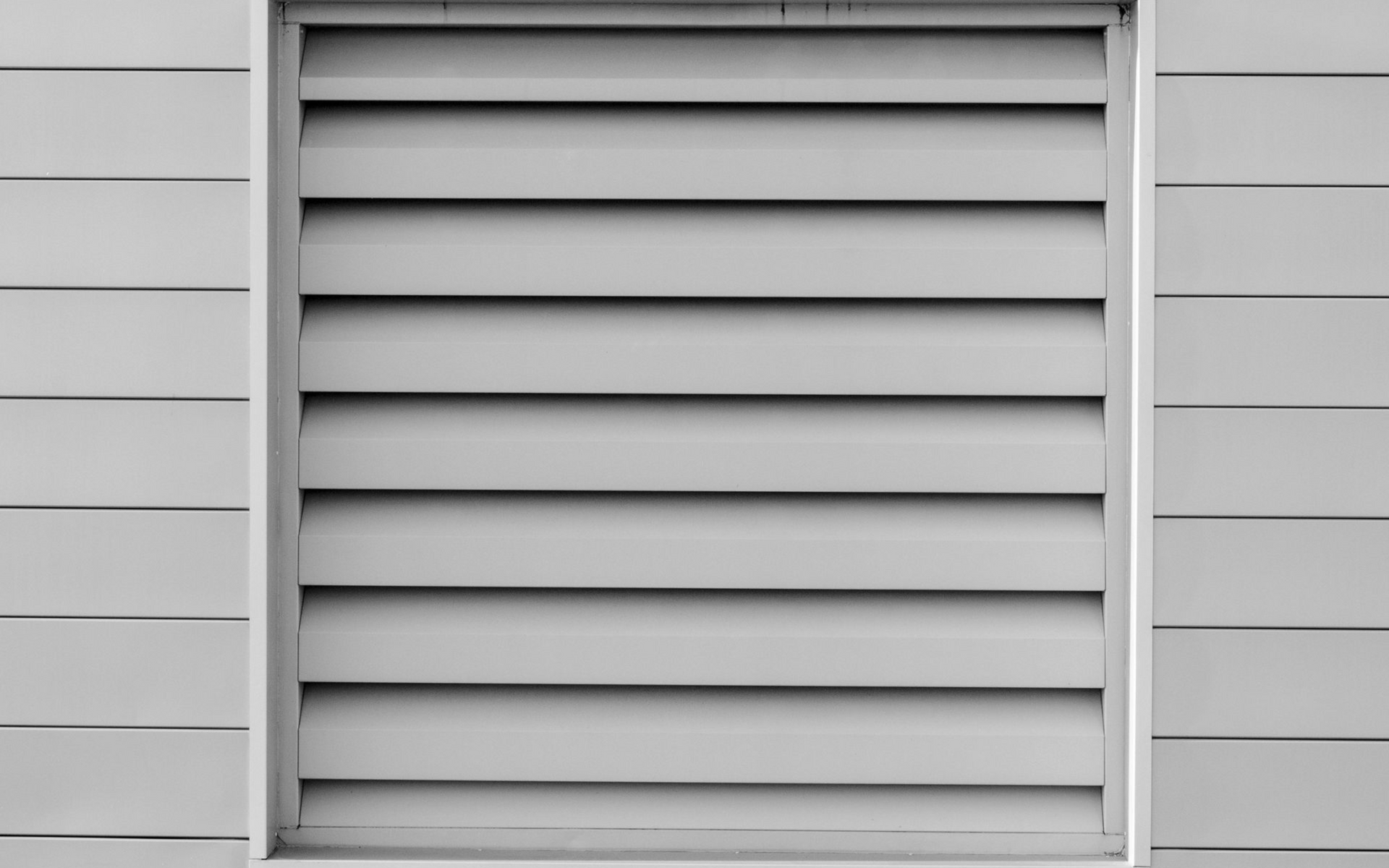

- Ensure proper attic ventilation (ridge vents, soffit vents).

- Use vapor barriers where appropriate.

Would you like this explained in a more visual, client-friendly format or converted into a social media post or blog draft?

You said:

yes

ChatGPT said:

Great! Here's a client-friendly visual-style blog post draft you can use as a website article, social media caption, or even part of a newsletter:

🏠 Why Low Attic Insulation Could Be Harming Your Home More Than You Think

Your attic might be "out of sight, out of mind"—but poor insulation up there can lead to some serious (and sneaky) problems. Here's why it matters 👇

🌬️ 1. Moisture Builds Up Fast

Warm air from inside your home rises into the attic. Without proper insulation, it meets cold surfaces and condenses—leading to water droplets that soak into wood and insulation. Hello, mold. 👋

💧 2. Your Attic Becomes a Humidity Trap

No insulation = no barrier. That lets humid air escape from your living space and settle into the attic, raising moisture levels and creating a breeding ground for mildew and decay.

🍄 3. Mold and Mildew Love It

Dark, damp, and warm? That’s mold’s dream home. Once it starts growing, it can spread quickly and ruin wood, drywall, and your indoor air quality.

❄️ 4. Ice Dams in Winter = Leaky Roofs

In colder climates, escaping heat melts snow on your roof. It refreezes at the edges, causing ice dams—and water backs up under shingles, leaking into the attic.

⚡ 5. You Pay More on Energy Bills

Humidity affects your HVAC efficiency. Systems in the attic have to work harder, which means you’re paying more to stay comfortable.

✅ What You Can Do:

- Boost your attic insulation (think fiberglass or blown-in cellulose).

- Seal off air leaks.

- Make sure your attic has proper ventilation.

- Add vapor barriers where needed.

A well-insulated attic = a healthier, drier, and more energy-efficient home. 🏡💸

Got questions about insulation? Drop them below or send us a message—we’re here to help!

https://www.insulationspokane.com/thermal-inspections